Spot Welder Problems . common spot welding problems. since weak spot welds may look similar to strong ones, how do you stay out of trouble? Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. Here are some suggestions for improving your resistance. the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Some of the most prominent spot welding problems are: Check whether the electrode pressure is too low, and check whether the electrode rod is tight.

from www.mdpi.com

Check whether the electrode pressure is too low, and check whether the electrode rod is tight. Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. common spot welding problems. the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. Here are some suggestions for improving your resistance. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Some of the most prominent spot welding problems are: since weak spot welds may look similar to strong ones, how do you stay out of trouble?

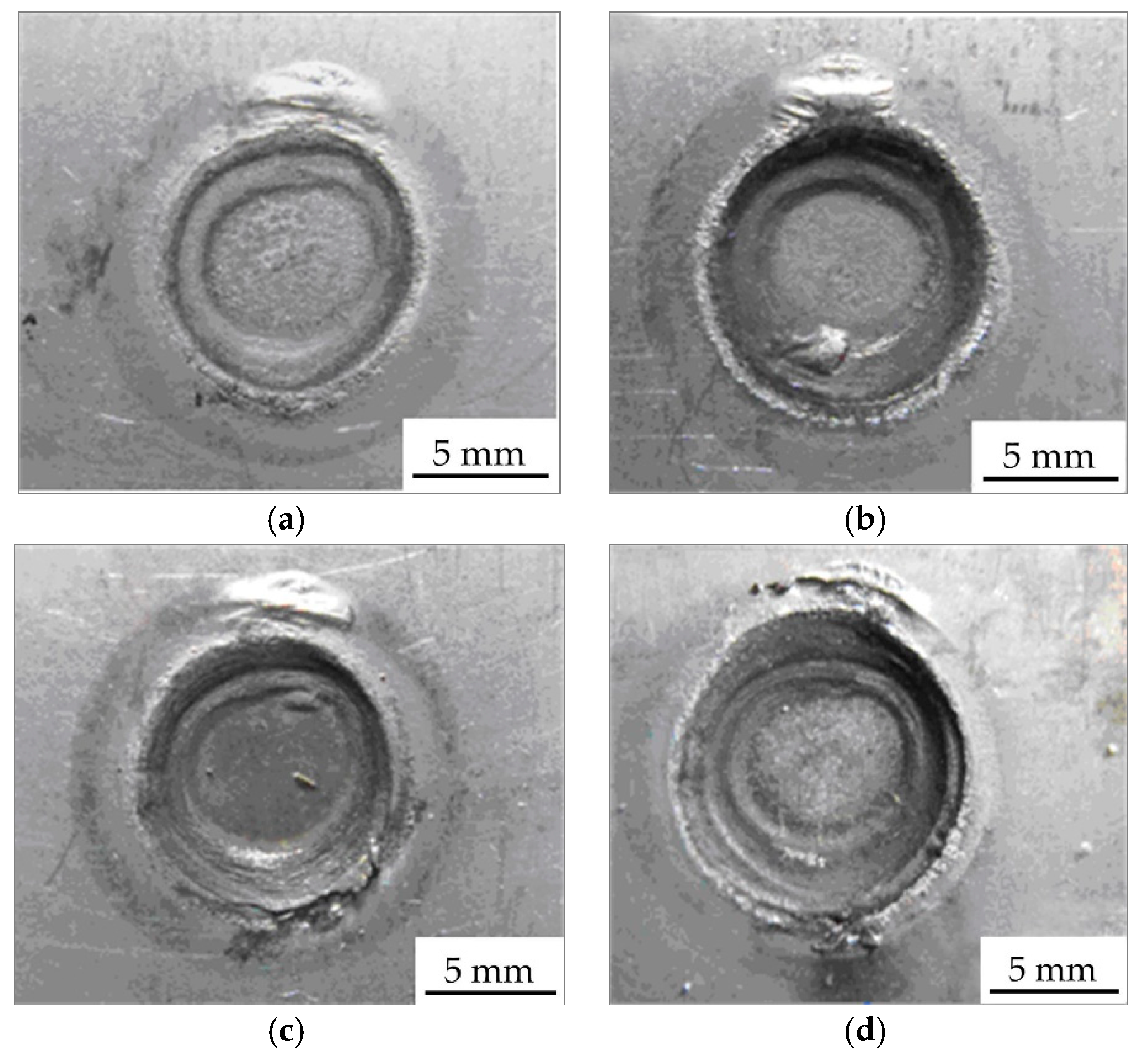

Materials Free FullText Effect of Welding Current on Weld Formation, Microstructure, and

Spot Welder Problems Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. common spot welding problems. Some of the most prominent spot welding problems are: spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. since weak spot welds may look similar to strong ones, how do you stay out of trouble? the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Check whether the electrode pressure is too low, and check whether the electrode rod is tight. Here are some suggestions for improving your resistance. Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints.

From blog.thepipingmart.com

What are Welding Defects? ThePipingMart Blog Spot Welder Problems surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. since weak spot welds may look similar to strong ones, how do you stay out of trouble? Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of. Spot Welder Problems.

From www.instructables.com

How to Make a Spot Welder for Cheap!! 11 Steps (with Pictures) Instructables Spot Welder Problems spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Check whether the electrode pressure is too low, and check whether the electrode rod. Spot Welder Problems.

From www.omsmeasure.com

Most common welding defects — OMS Optical Metrology Services Ltd Spot Welder Problems Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. Some of the most prominent spot welding problems are: surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Here are some suggestions for improving. Spot Welder Problems.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Spot Welder Problems the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding,. Spot Welder Problems.

From www.mdpi.com

Symmetry Free FullText Enhancement in Quality Estimation of Resistance Spot Welding Using Spot Welder Problems Some of the most prominent spot welding problems are: surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Here are some suggestions for improving your resistance. Check whether the electrode pressure is too low, and check whether the electrode rod is tight. since weak spot welds may. Spot Welder Problems.

From www.s-gala.com

Las Titik atau Spot Welding, Buat Apa Sih? Spot Welder Problems common spot welding problems. since weak spot welds may look similar to strong ones, how do you stay out of trouble? Some of the most prominent spot welding problems are: Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. surface splash and. Spot Welder Problems.

From omnirobotic.com

5 Common Welding Problems and How To Solve Them Omnirobotic Spot Welder Problems the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. Here are some suggestions for improving your resistance. Some of the most prominent spot welding problems are: surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Check whether the welding energy is. Spot Welder Problems.

From www.raymond-robert.com

SPOT WELDER WELDOMATIC Spot Welder Problems Some of the most prominent spot welding problems are: spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. Check whether the electrode pressure is too low, and check whether the electrode rod is tight. common spot welding problems. since weak spot welds. Spot Welder Problems.

From blog.thepipingmart.com

Spot Welding vs Tack Welding What's the Difference Spot Welder Problems spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. common spot welding problems. surface splash and electrode sticking are a result of excessive heating between the. Spot Welder Problems.

From www.wolfrobotics.com

Spot Welding Robotic Systems Spot Welder Problems since weak spot welds may look similar to strong ones, how do you stay out of trouble? surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. common spot welding problems. Check whether the electrode pressure is too low, and check whether the electrode rod is tight.. Spot Welder Problems.

From www.mdpi.com

Materials Free FullText Effect of Welding Current on Weld Formation, Microstructure, and Spot Welder Problems since weak spot welds may look similar to strong ones, how do you stay out of trouble? Check whether the electrode pressure is too low, and check whether the electrode rod is tight. Some of the most prominent spot welding problems are: Here are some suggestions for improving your resistance. common spot welding problems. the weldhelp resistance. Spot Welder Problems.

From www.monocoque-metalworks.com

The dangers of amateur welding!!! Monocoque Metalworks Spot Welder Problems surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. since weak spot welds may look similar to strong ones, how do you stay out of trouble? Here are some suggestions for improving your resistance. Check whether the welding energy is too small and whether the welding workpiece. Spot Welder Problems.

From marinerspointpro.com

Spot Welding Marinerspoint Pro Spot Welder Problems spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Here are some suggestions for improving your resistance. Some of the most prominent spot. Spot Welder Problems.

From knoxfr.com

Welding Defects And What They Are? How To Avoid Them! Knox Incorporated Spot Welder Problems Check whether the welding energy is too small and whether the welding workpiece is severely corroded, resulting in poor contact of the solder joints. surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. common spot welding problems. Some of the most prominent spot welding problems are: . Spot Welder Problems.

From xpressmobilewelding.com

What is Spot Welding? Spot Welder Problems spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. Here are some suggestions for improving your resistance. Some of the most prominent spot welding problems are: the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. surface. Spot Welder Problems.

From weldingweb.com

CarOLiner CTR 12000 Spot welder problems Spot Welder Problems surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Some of the most prominent spot welding problems are: common spot welding problems. Check whether the electrode pressure is too low, and check whether the electrode rod is tight. Here are some suggestions for improving your resistance. . Spot Welder Problems.

From www.theengineerspost.com

16 Common Types of Welding Defects [Causes, Remedies] PDF Spot Welder Problems spot welds provides rapid energy transfer to a concentrated area, distinguishing it from seam welding, projection welding, flash welding, upset welding, and stitch welding. Some of the most prominent spot welding problems are: Here are some suggestions for improving your resistance. the weldhelp resistance welding troubleshooting guide is written for operators and engineers to help diagnose. common. Spot Welder Problems.

From schematiclechfaniq.z4.web.core.windows.net

How To Use A Spot Welder Spot Welder Problems Some of the most prominent spot welding problems are: surface splash and electrode sticking are a result of excessive heating between the electrode and the sheet material being joined. Here are some suggestions for improving your resistance. Check whether the electrode pressure is too low, and check whether the electrode rod is tight. since weak spot welds may. Spot Welder Problems.